Torsion Spring

- Home

- Torsion Spring

Manufacturer & Supplier of

Torsion Spring

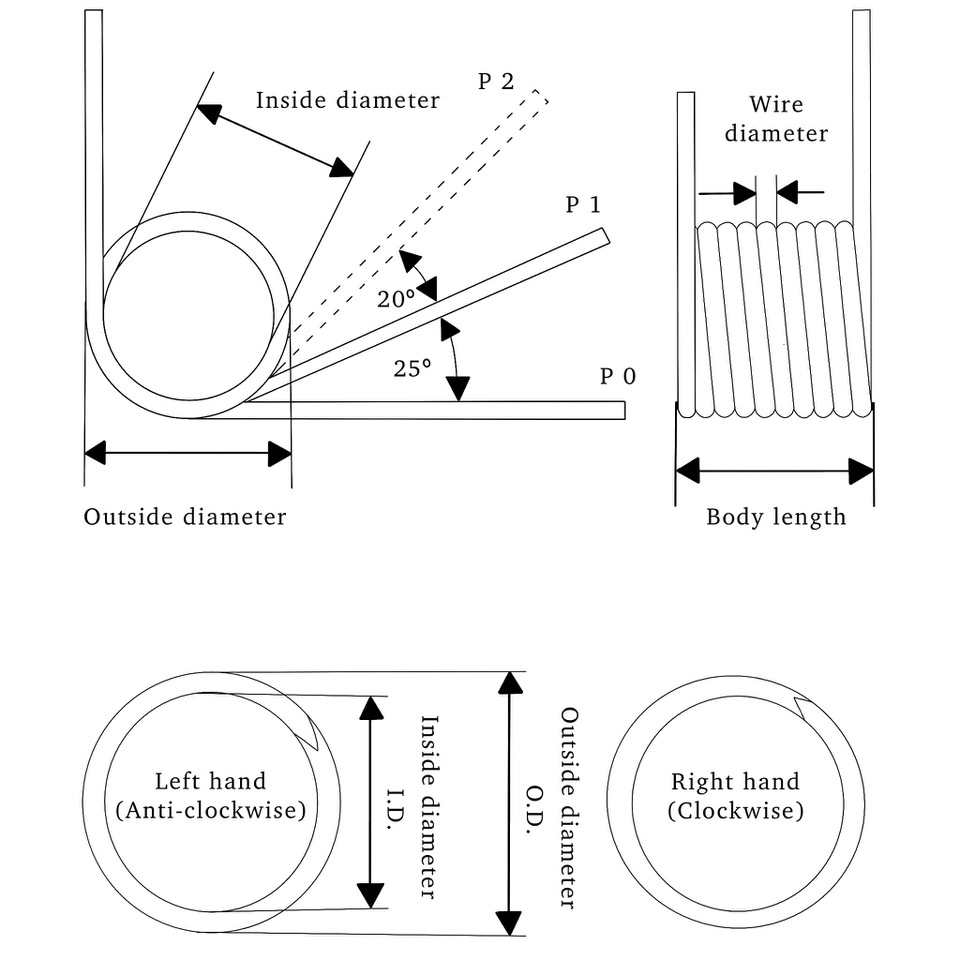

Torsion springs, or helical coil springs, are expertly engineered to handle torque, twisting, and rotary forces. These springs operate by twisting around their axis, generating a reactive torque in the opposite direction proportional to the angle of twist. Torsion springs are specifically designed to provide resistance to rotational forces, making them ideal for applications requiring controlled twisting motion.

Material

- Stainless Steel: Offers exceptional resistance to corrosion and maintains strength even in harsh environments.

- Carbon Steel: Provides a cost-effective option with good strength and durability for a range of applications.

- Alloy Steel: Enhances performance with superior strength and resilience, ideal for high-stress conditions.

- Music Wire: Known for its high tensile strength and flexibility, suitable for precision and heavy-duty uses.

- Phosphor Bronze: Combines strength with excellent wear resistance, making it suitable for high-cycle and demanding applications.

Finish

- Zinc Plating: Provides a protective layer that prevents rust and extends the lifespan of the spring.

- Galvanizing: Offers superior corrosion resistance, especially in outdoor or severe environments.

- Powder Coating: Adds a durable and attractive finish, enhancing both appearance and environmental resistance.

- Black Oxide: Creates a sleek, dark finish while offering moderate corrosion resistance and reducing glare.

- Passivation: Enhances the natural oxide layer on stainless steel to improve corrosion resistance and preserve appearance.

Manufacturing Process

Torsion Springs are manufactured on imported CNC Spring Multi forming Machines with its angle control by air control sensing device.